Quality Control

Quality Control

Quality Assurance

Efforts are taken in the manufacturing process to ensure highest quality standards that involve implementing systematic processes so that the GMT pallets meet specified requirements and customer expectations. This includes everything from product design and material selection to manufacturing process control, testing, and identifying and fixing potential issues. The goal is to prevent flaws and errors in the production process to deliver high-quality goods.

Results of our Quality Assurance:

- Improved Customer Satisfaction:

By delivering high-quality GMT pallets, we enhance our customer satisfaction which is nothing less than pure delight. - Enhanced Reputation:

A strong QA program has built our reputation for reliability and quality. - Compliance with Regulations:

We ensure compliance with industry standards and expectations, which can be crucial for international procurement.

Key Aspects of Quality Assurance for our GMT Pallets:

- Standard Compliance:

Our GMT pallets adhere to relevant international standards. - Product Design and Development:

Our GMT pallets meet specific design requirements and customer needs. - Raw Material Sourcing and Verification:

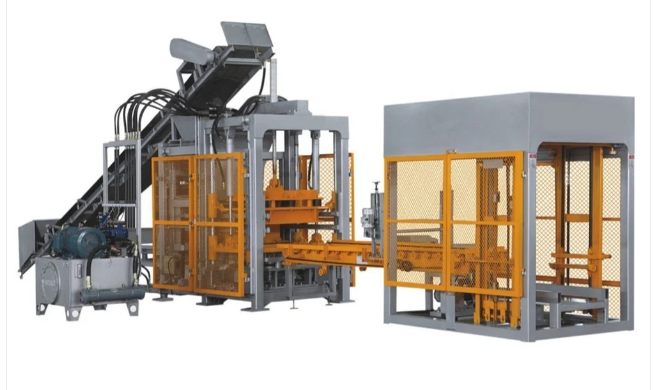

To make sure that our GMT pallets meet quality standards, raw materials of acceptable quality are carefully sourced. - Manufacturing Process Control:

The manufacturing process is monitored and controlled in every stage to prevent defects and ensure consistency. - Product Testing:

Various tests are conducted to evaluate the quality, functionality, and performance of the GMT pallets. - Inspection and Documentation:

Regular inspection is conducted and detailed documentation of the QA process is maintained. - Feedback and Improvement:

Continuous feedback gathering is done and improvements are made to the QA process and product development is mainly based on customer feedback and performance data.