The Best Alternative to Wooden Pallets in Fly Ash Brick Manufacturing

The best alternative to wooden pallets in fly ash brick and block manufacturing is GMT Pallets (Glass Mat Thermoplastic Pallets). Unlike wood, they do not absorb water, break under vibration, or get damaged by termites. With a lifespan of 8–10 years, GMT Pallets are stronger, more reliable, and far more cost-effective.

For years, wooden pallets were the common choice, but their drawbacks — short life, high maintenance, and recurring replacement costs — have forced manufacturers to look for better solutions. After exploring different materials, industries have found that the best alternative to wooden pallets for fly ash brick plants is GMT Pallets.

The Problem with Wooden Pallets

While wooden pallets are cheap and easily available, they create several issues in fly ash brick and block manufacturing:

Moisture Absorption – Wood absorbs water during curing, causing swelling, warping, and uneven surfaces.

Low Durability – Breaks and cracks under heavy load and machine vibration.

Termite and Decay Issues – Prone to termite attack and natural rotting.

Short Lifespan – Usually lasts only 1–2 years, requiring frequent replacements.

Higher Long-Term Cost – Frequent damage and replacements increase production expenses.

Because of these drawbacks, wooden pallets are no longer a reliable option for modern, high-volume brick production.

Alternatives Considered

In search of a better option, industries tested different materials:

PVC Pallets – Water-resistant but bend easily under heat and vibration.

Bamboo Pallets – Stronger than wood but still absorb moisture and lose shape over time.

Steel Pallets – Very strong but heavy, costly, and difficult to handle.

While each has some benefits, none offered the perfect balance of durability, performance, and cost-efficiency.

GMT Pallets: The Best Alternative to Wooden Pallets

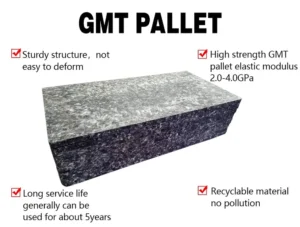

The most effective solution is GMT Pallets (Glass Mat Thermoplastic Pallets). Made from glass fiber mats reinforced with thermoplastic resin, they are designed for the demanding conditions of fly ash brick and block manufacturing.

Why GMT Pallets Stand Out

High Strength – Can withstand heavy loads and continuous vibration.

Long Lifespan – Lasts 8–10 years compared to just 1–2 years for wooden pallets.

Moisture and Termite Proof – Will not swell, warp, or decay.

Eco-Friendly – Manufactured from recycled thermoplastic materials.

Cost-Effective – Higher initial cost but big savings in the long run.

This makes GMT Pallets the best replacement for wooden pallets in the brick and block industry.

Conclusion

The industry has moved past wooden pallets because of their weaknesses. While PVC, bamboo, and steel offered temporary fixes, none could provide a complete solution.

Today, it’s clear: the best alternative to wooden pallets is GMT Pallets. With unmatched durability, strength, and cost benefits, they are the future of pallet technology in fly ash brick manufacturing.